Seems like out of nowhere Kviek yeast blasted onto the radar of homebrewers and now craftbrewers. Its the Norwegian Farmhouse yeast that has crazy temperature tolerances.

Brewers were claiming it to be producing clean ales and even “lagers” at temps reaching into the 90sF or even higher! And being done in as little as two days.

Sounds almost too good to be true. But the reports kept coming. So I finally gave it a few tries. My garage would be the perfect place to let it rip at 90 degrees.

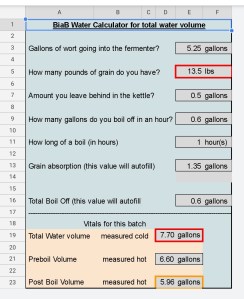

The best way to test new ingredients is of course to keep them as simple as possible, so a SmaSh beer (Single Malt and Single Hop) fits perfectly. I went with Munich malt, Magnum hops, and Hornindal Kviek.

This was August. Middle of summer. My garage, and everything else is in the 90s now. I get the beer brewed and the liquid Kviek pitched. Just have to wait for the “explosion” that’s supposed to happen.

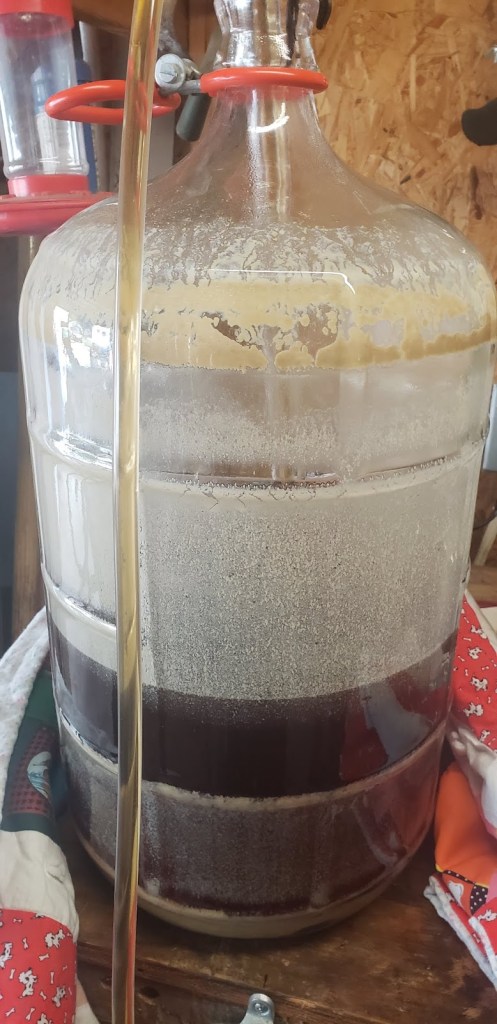

Fizzle… Nadda. First day there was nothing. You could just see the yeast clump laying on the bottom of the carboy. Just as I had figured this was gonna work. I’ll just let it sit just to make sure.

Day two was a completely different story. Nearly up and out of the 6.5 gallon carboy, and churning so hard the bench was rumbling. And then by day 3 it was nearly completely stopped. Day 4 everything dropped and halfway done clearing. Well,, as clear as Kviek gets. (More on that shortly)

Tasting notes from the first batch were just as people said it would be. Fruity and bright. No off flavors like you would expect from high temp ferment. But murky. Like a mud bomb went off in the carboy. And that yeast taste hung around in the keg for quite a while. But when it finally dropped it was very clean tasting. But never quite clear.

The second batch was Voss Kviek. Again a SmaSh, Munich, saaz, Voss. Again in the 90s

Pretty much right down the same stages as the Hornindal. A day of lag, then a day of violent ferment, then everything falls out and starts to clear by day 3.

Same results. Fruity, but a different fruity this time. More like fruit salad, but bright. And again muddy looking. And still yeasty tasting until the keg drops clear.. or clearer. It don’t really become clear. Not as hazy as a New England, but close.

One thing to note is that this yeast makes a ton of sludge. There must be two inches of yeast at the bottom. And seeing that, I wanted to try and save some. And I did what I read the farmers did to save this yeast. Dry it.

I grabbed a spruce branch right off the tree and swabbed it in the yeast cake and hung it in the garage. At 90F and a ceiling fan, it dried very quickly.

The next batch I made the beer as normal, and just took this stick of dried yeast, which you can see is pretty small. Like 3 inches or so. And chucked in into the wort.

This time we had activity going much sooner than pitching the liquid. But it did the same crazy ferment and drop as the other had.

Still dirty. But I’d say not as bad. But still it never really clears in the keg. Same tastes same aromas.

Come to find out that alot of people are getting better ferments by really under pitching. Using ¼ packet. Seems to help with the lag and esters.

And drying the cake is really popular for saving this yeast. Spread it in a pan, let it dry, break into pieces, freeze till needed, then just pitch a few dry hunks.

This yeast has some good qualities to it for sure. Some might not like that its never clear, I don’t mind. And there are more and more varieties out almost weekly.

There are many experiments that need to be done with these Kvieks, like the different profiles they give at different temps. Some say they are like having 3 different yeasts in the same package.

I’m gonna have to find out